Can artificial joints only last for 15 years?

- Why Botulinum Toxin Reigns as One of the Deadliest Poisons?

- FDA Approves Pfizer’s One-Time Gene Therapy for Hemophilia B: $3.5 Million per Dose

- Aspirin: Study Finds Greater Benefits for These Colorectal Cancer Patients

- Cancer Can Occur Without Genetic Mutations?

- Statins Lower Blood Lipids: How Long is a Course?

- Warning: Smartwatch Blood Sugar Measurement Deemed Dangerous

Can artificial joints only last for 15 years?

Can artificial joints only last for 15 years? How many years can artificial joints be used?

You need to understand the following four important points:

1. The statement that “artificial joints can only be used for 15 years” is wrong in this day and age!

2. After the emergence of ultra-high molecular weight cross-linked polyethylene, the service life of artificial joints can theoretically exceed the life of humans.

3. With the appearance of ceramic parts, the wear life is further extended, and the problem of wear particles can be ignored.

4. Therefore, for young patients, “age” is no longer a taboo for hip replacement.

If you want to take a closer look, please see the details:

01 How many years can artificial joints be used?

1. What determines the service life of joints?

Joint materials, prosthesis design, surgical techniques, physical conditions, activities, etc., will all affect the use of artificial joints. Among them, the material of the joint is the main influencing factor.

This is the same as when we buy a family car. The manufacturer will recommend a usage time for the car. The country sets the scrap standard for cars at 600,000 kilometers. How did this standard come out? This standard is calculated according to the aging time of automobile parts and materials. Similarly, our artificial joints will also have a service life setting. This is mainly related to the durability of the material. Simply put, it is how many years the components of the joint can wear.

At this time, some smart people may jump out and ask: “You said that the joints can be used for a lifetime, and that many materials have not been invented for decades. How do you know that they can be used for a lifetime?” This involves the development and testing of artificial joints. All artificial joint manufacturers will have a research and development department. The research and development department has a set of standardized detection methods for the wear of artificial joints. The use time of implantation in the body is estimated by the speed of external wear. For example, by simulating human body movement in vitro for one to several years, the measured amount of wear can be used to calculate how many years the material can be worn under the thickness of the finished product. Are you clear now?

2. Why the previous joints can only be used for 15 years?

Since the originator of our modern artificial joint surgery in the 1950s, Professor John Charnly of the United States put forward the theory of low friction, the “metal to polyethylene” artificial joint friction interface has become the “gold standard” of artificial joints. The life of artificial joints is mainly determined by the nature of the “friction interface”. So what is the “friction interface”? To clarify this issue, we must first let everyone know what an artificial hip joint is like.

Take a look at the picture below:

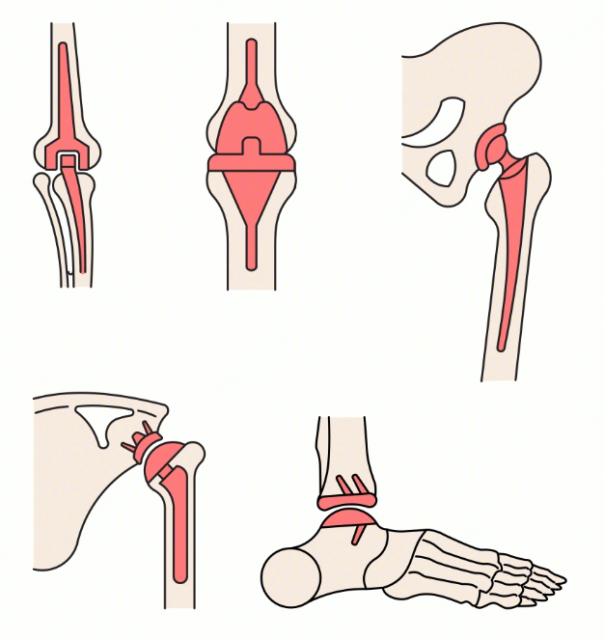

The hip prosthesis actually consists of four components.

- The top is a metal acetabular cup❶.

- A lining❷ is placed inside the acetabular cup.

- The inner lining faces the ball head❸, which is placed on the femoral stem ❹ .

- These four components constitute an artificial hip joint.

Among them, ❷❸, that is, the inner lining and the ball head constitute the so-called “friction interface”, because the acetabular cup ❶ and the femoral stem ❹ are ultimately to grow together with the bone, and the friction of the friction interface during the joint movement constitutes the friction interface. The main factor of joint wear and tear.

The speed of wear mainly depends on two factors: the smoothness of the interface and the wear resistance of the interface material. In fact, it is easy to understand, these are the basic principles of physics. The rougher the surface, the faster it wears; conversely, the smoother the surface, the slower it wears. The more wear-resistant the material, the slower the wear rate, and vice versa, the faster the wear rate.

Since the 1950s, the ball head part ❸ has been mainly made of metal, including stainless steel and cobalt-chromium-molybdenum. The latter is more wear-resistant. The inner lining part ❷ is mainly made of polyethylene, which is a plastic material. A friction interface composed of metal and plastic. Because the metal is hard and the plastic is soft, the plastic part is mainly damaged by friction. With this combination, the annual wear loss of polyethylene is about 200μm in thickness, and the thickness of a polyethylene liner is generally 3-5mm (3000μm-5000μm). We use the method of addition, subtraction, multiplication and division learned in elementary school to calculate one Calculate, if you want to wear out a polyethylene lining, it will be 15-25 years. In most cases, due to other factors (such as poor placement of the prosthesis caused by surgical techniques), the service life of the prosthesis is compromised. In addition, the dissolution of the wear particles on the human bone causes the “metal to polyethylene”. The service life of the prosthesis of the friction interface is generally about 15 years.

3. How many years can the current material grind?

The previous “metal-to-polyethylene” wear period was about 15 years, so for young patients, total hip replacement really cannot meet their lifetime needs. In order to change this situation, scientists continue to invest a lot of energy in the development of new materials to reduce the wear rate of the “friction interface”.

In this process, two revolutionary materials emerged:

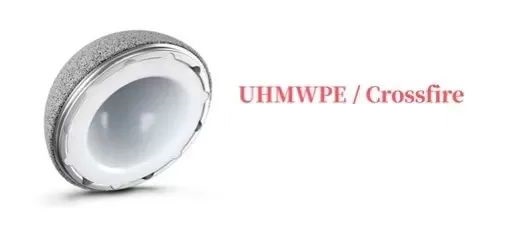

(1) The first is: ultra-high molecular weight cross-linked polyethylene.

On the basis of ordinary medical artificial joint polyethylene, scientists have tried to improve the production process. Through r-ray irradiation and post-heat treatment, “ultra-high molecular weight cross-linked polyethylene” is obtained. The emergence of this plastic makes the interface The wear rate of the plastic has been greatly reduced, and the oxidation resistance of the material has been improved at the same time, that is to say, this plastic is more wear-resistant and has a longer life.

At present, “ultra-high molecular weight cross-linked polyethylene” has evolved to the third generation, with better abrasion resistance and better oxidation resistance. Matched with the traditional metal ball head, the annual wear rate has dropped to 20μm/year. If the 3mm (3000μm) inner lining is worn through at this wear rate, it should theoretically take 150 years. In this way, it seems that the “metal to polyethylene” prosthesis can be used for a lifetime. However, in fact, due to the inflammation caused by worn-out plastic particles that dominates the occurrence of osteolysis, we believe that this kind of prosthesis cannot actually meet the lifetime needs of young patients as in theory after being implanted in the human body.

Artificial joint

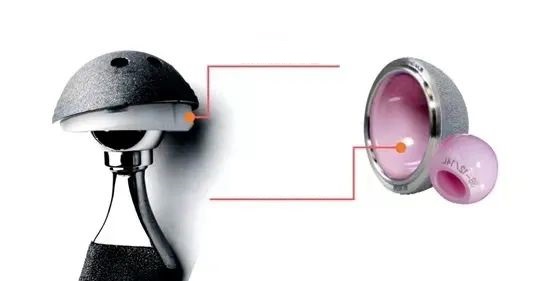

(2) A more revolutionary milestone: the invention of joint ceramic parts.

I personally believe that the emergence of joint ceramics should solve the age limit of hip replacement. Since ceramics can be made smoother (lower friction coefficient) than metals, the invention of ceramic parts has further reduced the wear speed of the friction interface, and this decline has reached an incredible level.

Why do you say “unbelievable”? It is because the smoothness of the ceramic interface is too good and the friction coefficient is extremely small, so the wear rate is very slow, to the point where it is almost negligible. The wear rate mentioned here refers not only to the ceramic part itself, but also to the other half of the wear rate that matches it. So how small is this kind of wear?

The friction interface is actually the two sides corresponding to each other. The ceramic part can be made into a ball head or an inner lining. Therefore, there are actually two types of “friction interfaces” composed of ceramic parts, one is “ceramic ball head” versus “ceramic lining”, and the other is “ceramic ball head” versus “ultra-high molecular weight cross-linked polyethylene lining”. “. The wear rate of these two interfaces is different.

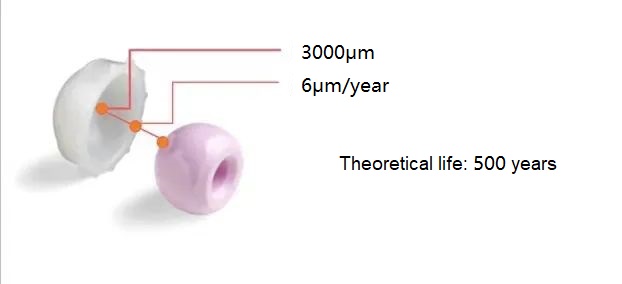

First look at the wear rate of the “ceramic ball head” to the “ultra-high molecular weight cross-linked polyethylene lining” (ceramic to polyethylene, also known as semi-ceramic). Calculated by the fourth-generation powder pottery (the third-generation yellow pottery has been eliminated), the wear rate of this friction interface is about 6μm per year. If the wear time is calculated according to the polyethylene lining 3mm (3000μm), theoretically It takes nearly 500 years for the vinyl lining to wear through.

Of course, this kind of interface still has the problem of polyethylene wear particles (although the number of particles is almost negligible compared to before), the osteolytic effect of the particles itself is undeniable, so even if humans can live to 500 years old, we must not I think that this kind of prosthesis can really be used in the body for 500 years, but even if it is a 1 to 2 discount, there will be 50-100 years left, which is definitely satisfactory for human use.

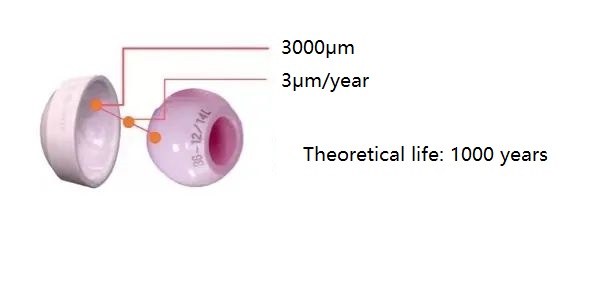

Secondly, let’s take a look at the wear rate of the “ceramic ball head” to the “ceramic lining” (pottery-to-ceramic, also called full ceramic). Calculated by the fourth-generation powder ceramic, the wear rate of this friction interface is about 3μm per year, if the wear time is calculated according to the polyethylene lining 3mm (3000μm), theoretically it will take nearly 1000 years to wear the polyethylene lining. In other words, it is absolutely enough for people.

It has to be said that the invention of ceramic components really solves the problem of operation timing for young patients. Whether it is a full ceramic prosthesis or a semi-ceramic prosthesis, it is enough to meet the needs of a lifetime. Therefore, we are really grateful to the scientists who invented joint ceramics, which have substantially improved the quality of life of patients with femoral head necrosis around the world.

However, it is a pity that this kind of joint material cannot be produced in our country at present, and the industrial threshold of this material science is too high, even higher than that of “mobile phones and computer chips.” We all know that although we are stuck with chips by the United States, our country can still make chips with low craftsmanship (such as 28nm), but our country is really unable to produce the fourth-generation powder ceramics. This is Determined by the level of the country’s overall high-precision industry. However, not only us, but even the United States is currently unable to produce products that are comparable to existing joint ceramics. At present, 90% of the world’s ceramic products are from a German company.

02 Should I choose all-ceramic or semi-ceramic?

The all-ceramic refers to the joint between the “ceramic ball head” and the “ceramic lining”, and the semi-ceramic refers to the joint between the “ceramic ball head” and the “polyethylene lining”.

The price of full ceramics is more expensive than the price of semi-ceramics. Under normal circumstances, the price difference is between 10,000 and 20,000. So does it mean that all-ceramics are better than semi-ceramics? In fact, there is no direct comparison between the two based on the price. There is no absolute one who is good and who is not. All ceramics and semi-ceramics each have their own advantages and disadvantages.

The advantage of all-ceramics is that both ends of the friction interface are ceramics. The worn particles belong to minerals. The degree of mineral particles inducing the inflammatory response of macrophages in the body is much lower than that of polyethylene particles, which means that all-ceramics wear The osteolytic effect of particles is smaller than that of semi-ceramics.

But all ceramics also have three fatal disadvantages.

First, compared to the “hard-to-soft” interface of semi-ceramic joints (hard: ceramic ball head, soft: polyethylene lining), full ceramic is a “hard-to-hard” interface (hard: ceramic ball head, Hard: ceramic lining), so all-ceramic parts are more prone to chipping. Although the incidence of this kind of chipping has been greatly reduced on the fourth-generation powder ceramics, this possibility still exists.

The problem of revision after fragmentation has always been a big headache for joint surgery, because after fragmentation, ceramic debris cannot be completely cleaned from the joint. The presence of a large number of fine ceramic particles invisible to the naked eye will cause implantation.

The wear rate and fragmentation rate of revision joints will be greatly improved in the future, so the choice of prosthesis is very difficult and controversial: some doctors choose semi-ceramic joints for revision, allowing the existing ceramic particles to be squeezed into the polyethylene The inner lining, in this case, the smoothness of the interface decreases, and the wear life of the polyethylene is greatly reduced.

Some doctors still choose all-ceramic joint revisions, but the interface wear rate has greatly increased, and the risk of re-fragmentation of ceramic components has also increased significantly.

Second, as mentioned earlier, the risk of ceramic fragmentation is very high, so the ceramic parts must be made into a regular shape, that is to say, the ceramic lining does not have the anti-dislocation high side on the polyethylene lining. Therefore, the incidence of dislocation after implantation of all-ceramic joints is higher than that of semi-ceramic joints.

Third, there is the problem of abnormal noises in all ceramics. The so-called abnormal noises are abnormal noises that should not occur. This situation has a high incidence in European and American countries, but the incidence in China is relatively low. It may be related to body weight. It’s a certain relationship, but the abnormal noise that happened to the thin Chinese people can’t be explained. Although the abnormal noise is not a big problem, and it does not seem to be directly related to the broken ceramics, it is really annoying to take a step, and even some people around the noise can hear it, causing great trouble to life.

Although the wear rate of all ceramic and semi-ceramics seems to be twice the difference, one is 6μm and the other is 3μm, but in fact they are all within 10μm. This wear rate is actually negligible, and the number of wear particles is also negligible. There will be no orders of magnitude difference. Therefore, whether it is full ceramic or semi-ceramic, it can meet the life-long needs of patients, which is why in the United States, the vast majority of artificial hip prostheses implanted by patients are semi-ceramic joints.

Of course, the choice is in the hands of the patient. If you really have a psychological entanglement about the wear rate, then choose the all-ceramic joint, but the premise is to find an experienced doctor to avoid poor prosthesis position, which will increase the probability of joint dislocation. .

(source:internet, reference only)

Disclaimer of medicaltrend.org