COVID-19: Meltblown Fabric (Filter of Masks)

- Normal Liver Cells Found to Promote Cancer Metastasis to the Liver

- Nearly 80% Complete Remission: Breakthrough in ADC Anti-Tumor Treatment

- Vaccination Against Common Diseases May Prevent Dementia!

- New Alzheimer’s Disease (AD) Diagnosis and Staging Criteria

- Breakthrough in Alzheimer’s Disease: New Nasal Spray Halts Cognitive Decline by Targeting Toxic Protein

- Can the Tap Water at the Paris Olympics be Drunk Directly?

COVID-19: Meltblown Fabric (Filter of Masks)

- Should China be held legally responsible for the US’s $18 trillion COVID losses?

- CT Radiation Exposure Linked to Blood Cancer in Children and Adolescents

- Can people with high blood pressure eat peanuts?

- What is the difference between dopamine and dobutamine?

- What is the difference between Atorvastatin and Rosuvastatin?

- How long can the patient live after heart stent surgery?

COVID-19: Meltblown Fabric (Filter of Masks). Detailed explanation of meltblown cloth production technology, what are the core influencing factors?

As the core component of masks, meltblown cloth has become the most demanding material in the current mask production chain.

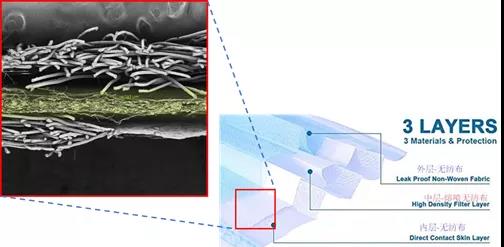

Medical surgical masks (structure shown in Figure 1) are usually composed of three layers of non-woven fabrics, the middle layer plays the most important role of filtering and barrier, and the material used is melt-blown non-woven fabric.

Figure 1 Mask structure diagram

Figure 1 Mask structure diagram

Melt blown cloth looks nothing special, but the production process is very complicated. Its production process can be summarized into three parts: firstly, naphtha is extracted from petroleum, then chemically processed into polypropylene, and finally the cloth is made by melt blown process. The general process is shown in Figure 2. The last link is mainly introduced here.

Figure 2 Meltblown cloth production process

Figure 2 Meltblown cloth production process

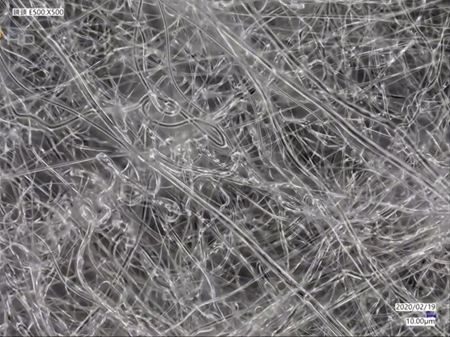

1. the choice of raw materials

Polypropylene (PP) is easy to form filaments, and when the melt index is high (MFI≥1500g/10min), it can become a fairly thin fiber (diameter of 2 to 3 μm). As shown in Figure 3, although the prepared melt blown cloth has a much larger gap than the size of the new coronavirus (about 0.1 μm), its ability to filter viruses in the environment is still very strong.

Because, first, the virus cannot exist independently, and its main transmission routes are secretions and droplets during sneezing. The size of the droplets is about 5 μm; second, the meltblown cloth is essentially a fiber filter, containing When the virus droplets are close to the meltblown cloth, they will also be electrostatically adsorbed on the surface and cannot penetrate.

2. Production process

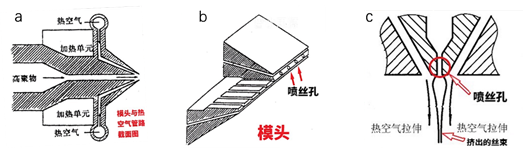

The production process of melt blown cloth is mainly divided into three steps: melt extrusion, melt blown process and electret treatment. The specific flow diagram is shown in Figure 4.

Relying on the screw extruder to melt the polymer particles to the molten die assembly, including the polymer distribution system, die system, drafting hot air pipeline channels and heating and heat preservation elements, and extrude them from the nozzle holes of the die . The diameter of the spinneret holes in the meltblown process is much smaller than the spinneret holes used in the inner and outer spunbond fabrics because the diameter of the meltblown fabric fibers is only one tenth of that of the spunbonded fabric fibers.

In order to achieve the required fineness, in addition to relying on smaller spinneret holes, the melt fibers need to be drawn by high-speed hot air streams on both sides at the same time as the spinneret holes are extruded (Figure 5c). The air is mixed with hot air, which can cool and solidify the attenuated melt.

The ultrafine fibers that have been drawn and solidified by cooling are blown to the condensation net curtain under the action of the drafting airflow. There is a vacuum suction device at the bottom of the condensation net curtain, which can adsorb the fibers on the condensation net curtain and use its own waste heat to bond the net together.

Finally, the most important thing is the electret treatment. The emitter electrode on the spinning line can make the melt-blown fiber have a permanent static charge, so that the melt-blown cloth has an additional electrostatic adsorption effect without hindering breathing. The non-woven fabric produced by the meltblown method has 35% filtration performance, and the filtration performance can be increased to 95% after electret treatment.

3. Factors affecting the quality of melt blown cloth

a. MFI of polymer raw materials

As the best barrier layer for masks, melt-blown cloth is a very fine material with many crisscross microfibers stacked in random directions. Take PP as an example. The higher the MFI, the finer the filaments drawn during melt-blown processing and the better the filtration performance.

b. Hot air velocity

Under the conditions of the same temperature, screw speed and receiving distance (DCD), the faster the hot air speed, the smaller the fiber diameter, the softer the hand of the non-woven fabric and the more fiber entanglement, resulting in a denser and smoother fiber web. Strength increases.

c. Hot air jet angle

The hot air jet angle (see Figure 5a) mainly affects the stretching effect and fiber shape. The smaller the angle will promote the formation of parallel fiber bundles, resulting in poor uniformity of the non-woven fabric. If the angle tends to 90°, a highly dispersed and turbulent airflow will be generated, which is beneficial to the random distribution of fibers on the condensed mesh curtain, and the finally obtained meltblown cloth has good anisotropic properties.

d. Receiving distance (DCD)

Too long a receiving distance will cause the longitudinal and transverse strength and bending strength to decrease, the non-woven fabric feels fluffy, and it will cause the filtration efficiency and filtration resistance to decrease in the meltblown process.

e. Screw extrusion speed

In the case of constant temperature, the screw extrusion rate should be maintained within a certain range. Before a certain critical point, the faster the extrusion speed, the higher the quantitative and the greater the strength of the melt-blown cloth; when it exceeds the critical value, the strength of the melt-blown cloth decreases, especially when MFI>1000, which may be Because the extrusion rate is too high, the wire strands are not sufficiently drafted and the threads are severely combined, so that the bonding fibers on the cloth surface are reduced and the strength of the meltblown cloth is reduced.

Disclaimer of medicaltrend.org